Last Updated: December 20, 2025

Planning a new sidewalk for your property can feel overwhelming when you’re facing unclear pricing, conflicting contractor quotes, and uncertainty about local permit requirements. What should be a straightforward home improvement project becomes a maze of questions: How much will it actually cost? Are you paying too much? What factors drive the price up or down in Lawrence, KS specifically?

We’ve installed hundreds of concrete sidewalks throughout Douglas County, from the tree-lined streets near the University of Kansas campus to the newer subdivisions in West Lawrence. Our teams know firsthand how local soil conditions, municipal codes, and seasonal weather patterns affect both pricing and installation quality. This guide breaks down exactly what you’ll pay for concrete sidewalk installation in Lawrence, KS, what influences those costs, and how to ensure you’re getting quality work that lasts decades.

Quick Answer: What Does Concrete Sidewalk Installation Cost in Lawrence, KS?

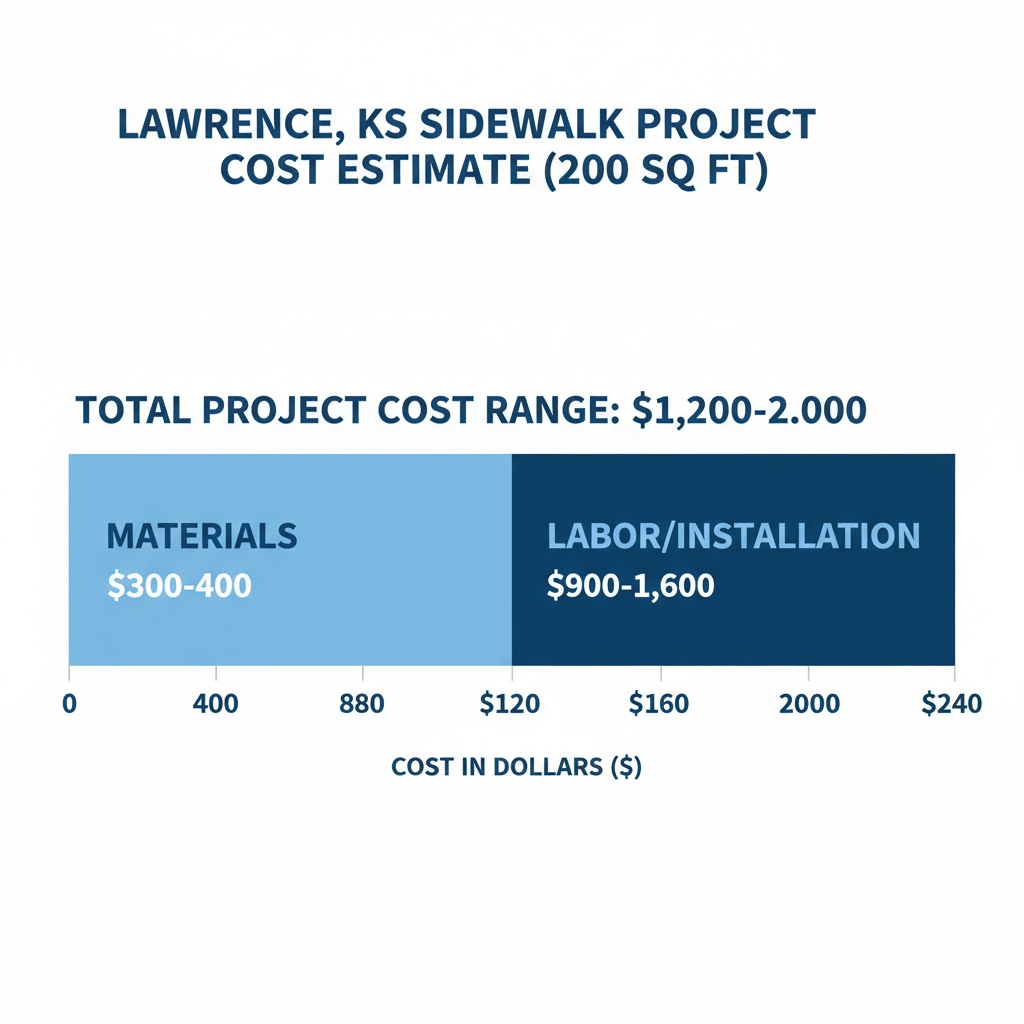

Concrete sidewalk installation in Lawrence, KS typically costs between $8 and $12 per square foot installed, with most homeowners paying around $10 per square foot. A standard 50-foot by 4-foot sidewalk (200 square feet) averages $1,600 to $2,400. Final costs depend on site preparation needs, concrete thickness, finishing options, and current permit requirements from the City of Lawrence.

Key Cost Factors in Lawrence, KS:

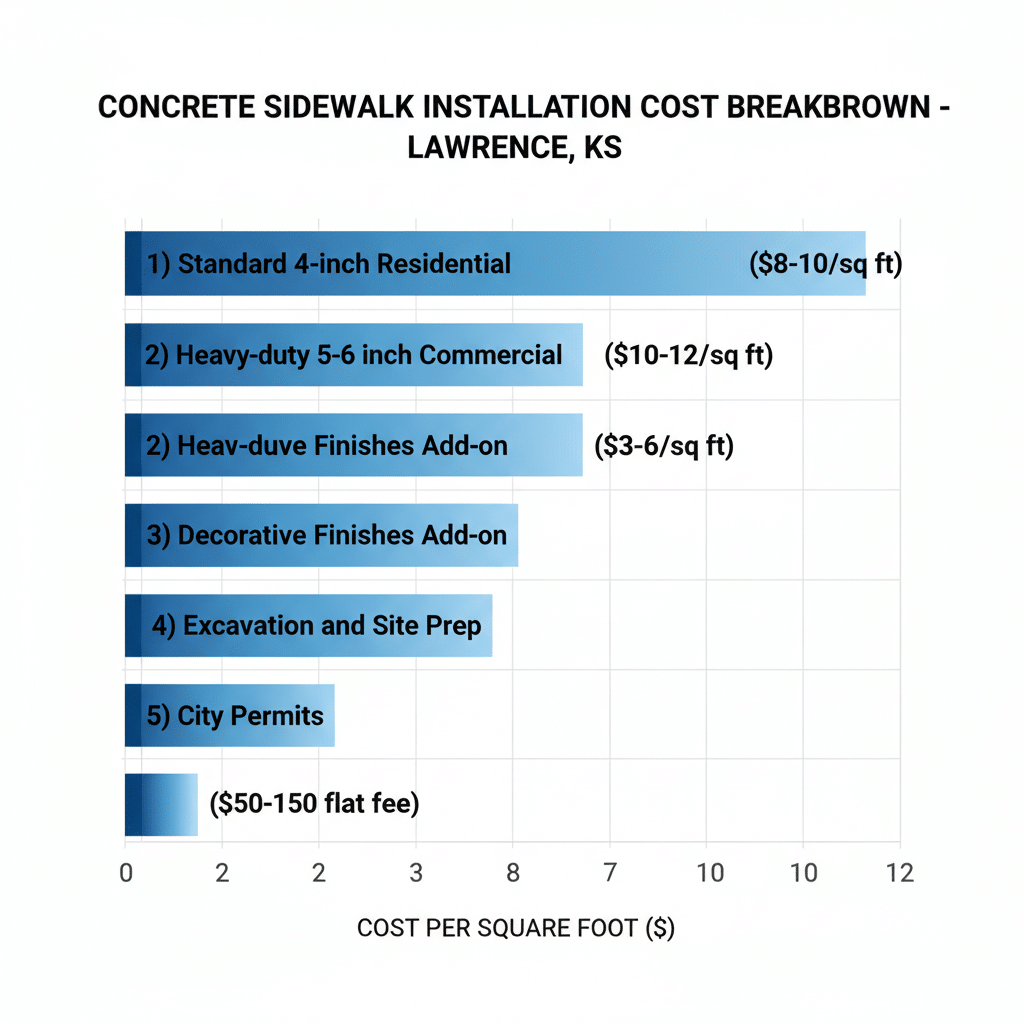

- Standard 4-inch residential sidewalk: $8-$10 per square foot

- Heavy-duty 5-6 inch commercial sidewalk: $10-$12 per square foot

- Decorative finishes (stamped, colored): Add $3-$6 per square foot

- Excavation and site prep: $2-$4 per square foot (if needed)

- City of Lawrence permits: $50-$150 depending on project scope

Understanding Concrete Sidewalk Installation Pricing in Lawrence, KS

When we price sidewalk projects throughout Lawrence—whether near the intersection of Massachusetts Street and 6th Street downtown or in the residential areas around Clinton Lake—we consider multiple cost components that affect the final price. Understanding these elements helps you evaluate contractor quotes accurately and avoid surprises.

Material Costs and Concrete Mix Specifications

Concrete costs fluctuate based on regional demand and supply chain factors. As of December 2025, ready-mix concrete in Lawrence runs approximately $120-$150 per cubic yard delivered. For a standard 4-inch thick sidewalk, you’ll need about 0.012 cubic yards per square foot, translating to roughly $1.50-$2.00 per square foot for materials alone.

The concrete mix design matters significantly for sidewalk longevity. We typically use a 3,000-4,000 PSI mix with air entrainment—critical for Lawrence’s freeze-thaw cycles. Properties near the Kansas River or low-lying areas may require additional waterproofing additives, increasing material costs by $0.25-$0.50 per square foot.

Labor and Installation Costs

Labor represents 50-60% of total project costs. Professional concrete installation requires skilled crews who understand proper subgrade preparation, reinforcement placement, finishing techniques, and control joint spacing. In Lawrence, labor rates for experienced concrete crews range from $45-$65 per hour, with a typical sidewalk installation requiring 2-3 workers for efficient completion.

Our crews working in established neighborhoods like Old West Lawrence or East Lawrence often encounter challenges that increase labor time: mature tree roots requiring careful excavation, existing utilities that need protection, or uneven grades requiring additional form work. These factors can add 15-25% to baseline labor costs.

Site Preparation and Excavation Requirements

Lawrence’s clay-heavy soils require proper excavation and base preparation to prevent settling and cracking. We typically excavate 8-10 inches deep: 4 inches for the concrete slab and 4-6 inches for compacted aggregate base. Excavation and haul-away costs range from $2-$4 per square foot depending on soil conditions and disposal fees at local facilities.

Properties in areas with poor drainage—common near Burcham Park or along portions of the Wakarusa River—may need additional grading work or French drain installation to prevent water accumulation under the sidewalk. These drainage improvements add $500-$1,500 to project costs but are essential for long-term performance.

Lawrence-Specific Factors That Affect Sidewalk Installation Costs

Working throughout Douglas County has taught us that local conditions significantly impact both pricing and installation approaches. Lawrence presents unique challenges that contractors from outside the area often underestimate.

Municipal Permit Requirements and Regulations

The City of Lawrence requires building permits for most sidewalk installations, particularly those in public rights-of-way or that connect to city sidewalks. Permit fees typically range from $50-$150 depending on project scope. Applications must include site plans showing dimensions, setbacks, and drainage details.

Douglas County also enforces stormwater management regulations that affect sidewalk installation. Projects must demonstrate proper runoff management, which may require permeable pavers, drainage swales, or connection to existing stormwater systems. Our teams factor these requirements into every bid to ensure compliance with local codes.

Seasonal Considerations and Weather Impacts

Lawrence’s climate creates distinct installation windows. While concrete work is possible year-round, optimal conditions occur from April through October when temperatures consistently stay above 50°F during curing. Winter installations require heated enclosures and cold-weather concrete mixes, adding $1-$2 per square foot to costs.

Spring demand peaks as homeowners plan summer projects, potentially increasing prices by 10-15%. Our scheduling data shows that late summer and early fall (August through October) often offer more competitive pricing as contractors fill schedules before winter slowdowns.

Accessibility and Site Logistics

Properties in established Lawrence neighborhoods often have limited access for concrete trucks and equipment. Narrow streets, mature landscaping, and fenced yards can complicate material delivery. When concrete trucks can’t reach the installation site, we use wheelbarrows or concrete pumps—adding $200-$800 depending on distance and quantity.

Projects near the University of Kansas campus require additional coordination for parking restrictions and pedestrian traffic management. These logistical challenges don’t necessarily increase material costs but do extend installation time and labor expenses.

Common Mistakes That Increase Concrete Sidewalk Costs

After decades installing sidewalks throughout Lawrence, we’ve seen recurring mistakes that inflate costs or lead to premature failure. Avoiding these pitfalls saves money both immediately and over the sidewalk’s lifespan.

Choosing Contractors Based Solely on Price

The lowest bid rarely delivers the best value. We regularly repair sidewalks installed by cut-rate contractors who skipped critical steps: inadequate base preparation, insufficient reinforcement, or improper control joint placement. These shortcuts create sidewalks that crack, settle, or spall within 2-3 years—requiring complete replacement.

A quality concrete sidewalk properly installed should last 30-50 years with minimal maintenance. Spending an extra $500-$1,000 upfront for experienced contractors with proven track records saves thousands in premature replacement costs. Always verify contractor licensing, insurance, and references from recent Lawrence-area projects.

Inadequate Site Preparation

Lawrence’s expansive clay soils require proper base preparation to prevent settlement. We’ve repaired numerous sidewalks where contractors poured directly on native soil without aggregate base or proper compaction. This “shortcut” saves $400-$800 initially but almost guarantees settling and cracking within five years.

Proper preparation includes: removing organic material and unsuitable soils, installing 4-6 inches of compacted Class 5 aggregate base, and ensuring proper drainage away from structures. These steps add time and cost but are non-negotiable for long-term performance.

Ignoring Drainage Requirements

Many homeowners overlook drainage planning during sidewalk installation. Sidewalks should slope 1/8 to 1/4 inch per foot away from buildings to prevent water intrusion. Properties in low-lying areas near the Wakarusa River or Clinton Lake need additional drainage measures—catch basins, channel drains, or permeable sections.

Failing to address drainage creates multiple problems: water pooling that accelerates freeze-thaw damage, foundation moisture issues, and ice hazards in winter. Proper drainage design adds minimal cost during installation but prevents expensive repairs later.

Best Practices for Cost-Effective Sidewalk Installation

Smart planning and informed decisions help you maximize value from your sidewalk investment. Our expert installation approach balances upfront costs with long-term performance.

Get Multiple Detailed Quotes

Request quotes from at least three licensed contractors with established Lawrence track records. Quality quotes should itemize: excavation and haul-away, aggregate base material and installation, concrete materials and labor, finishing and sealing, permit fees, and warranty terms. Vague lump-sum quotes make comparison impossible and often hide cost-cutting measures.

Ask contractors to specify: concrete PSI rating, reinforcement type (wire mesh or fiber), base material specifications, curing methods, and control joint spacing. These details reveal whether contractors plan proper installation or shortcuts that compromise quality.

Consider Timing and Bundling Projects

Combining multiple concrete projects—sidewalks, patios, or driveway replacement—reduces per-square-foot costs through mobilization efficiency. When our crews set up for one concrete project, adding related work costs significantly less than separate mobilizations.

Scheduling during contractors’ slower periods (late fall or early spring) often yields 10-15% price reductions. However, balance savings against optimal curing conditions—extremely hot or cold weather complicates installation and may compromise quality despite careful techniques.

Invest in Quality Finishing and Protection

Proper finishing and sealing extend sidewalk life significantly. We apply penetrating sealers that protect against moisture intrusion, freeze-thaw damage, and salt deterioration—critical for Lawrence’s winter conditions. Quality sealers cost $0.50-$1.00 per square foot but can double concrete lifespan.

For decorative sidewalks that enhance curb appeal near Massachusetts Street or the downtown area, stamped or colored concrete adds character without sacrificing durability. These decorative options cost more initially but create distinctive landscapes that complement Lawrence’s diverse architectural styles.

Step-by-Step: The Professional Sidewalk Installation Process

Understanding proper installation helps you evaluate contractor competence and monitor work quality. Here’s how professional crews should approach your sidewalk project in Lawrence.

Pre-Installation Planning and Permitting

Professional contractors begin with site evaluation, measuring exact dimensions, and assessing soil conditions and drainage patterns. We mark underground utilities through Kansas 811 (free service required by law) and develop detailed plans showing sidewalk layout, grades, and drainage features.

Permit applications go to the City of Lawrence Planning and Development Services, typically requiring 3-5 business days for approval. Projects in historic districts or near protected areas may need additional review time. Starting work without proper permits risks stop-work orders and fines up to $500.

Excavation and Base Preparation

We excavate to proper depth (typically 8-10 inches), remove unsuitable materials, and ensure proper slope for drainage. The aggregate base—usually 4-6 inches of Class 5 limestone or recycled concrete—is installed in lifts and compacted to 95% density using plate compactors or vibratory rollers.

Proper compaction prevents settling—a common cause of cracked sidewalks in Lawrence. We verify compaction with density testing on large projects to ensure specifications are met. Edge forms are installed using straight lumber or flexible forms for curves, precisely leveled and staked.

Concrete Placement and Finishing

Concrete delivery is coordinated for continuous placement—cold joints weaken sidewalks. We place reinforcement (wire mesh or fiber reinforcement) at mid-depth for crack control. Concrete is screeded level, floated to smooth the surface, and edged for rounded corners that resist chipping.

Control joints are cut or tooled every 4-5 feet to control where cracks form (they should occur at joints, not randomly). Final finishing includes brooming for slip resistance—essential for safe pedestrian use in Lawrence’s wet or icy conditions. Proper timing of finishing operations is critical; working concrete too early or late compromises surface quality.

Curing and Protection

Proper curing develops concrete’s full strength and durability. We apply curing compounds or keep surfaces moist for 7 days minimum. New sidewalks need protection from traffic, pets, and debris during curing. According to the Portland Cement Association, properly cured concrete reaches approximately 70% of design strength in 7 days and continues strengthening for months.

After curing, we apply penetrating sealers for additional protection. Final cleanup includes removing forms, backfilling edges, and restoring landscaping. A final walkthrough ensures quality and addresses any concerns before project completion.

Comparing Sidewalk Costs to Related Concrete Projects

Understanding how sidewalk pricing compares to other concrete work provides helpful context for budgeting home improvements.

| Project Type | Cost Per Square Foot | Typical Size | Average Total Cost |

|---|---|---|---|

| Basic Sidewalk (4″) | $8-$10 | 200 sq ft | $1,600-$2,000 |

| Decorative Sidewalk | $12-$15 | 200 sq ft | $2,400-$3,000 |

| Concrete Patio | $8-$12 | 300 sq ft | $2,400-$3,600 |

| Concrete Driveway | $8-$12 | 600 sq ft | $6,000 |

| Concrete Steps | $15-$25 | 30 sq ft | $450-$750 |

Sidewalks typically cost less per square foot than driveways despite similar thickness because they require less excavation, simpler reinforcement, and easier access for finishing work. However, narrow widths and longer perimeters relative to area can increase labor intensity.

Frequently Asked Questions About Sidewalk Installation Costs

How long does concrete sidewalk installation take in Lawrence, KS?

A standard residential sidewalk (150-250 square feet) typically requires 2-3 days: one day for excavation and base preparation, one day for concrete placement and finishing, plus 7 days minimum curing time before regular use. Larger projects or those requiring significant site work may take 4-5 days for active installation.

Do I need a permit for sidewalk installation in Lawrence, KS?

Yes, most sidewalk installations in Lawrence require building permits, particularly those in public rights-of-way or connecting to city sidewalks. Contact the City of Lawrence Planning and Development Services at (785) 832-3150 for specific requirements. Permit fees typically range from $50-$150 depending on project scope.

What’s the best time of year to install concrete sidewalks in Lawrence?

Optimal installation occurs from April through October when temperatures consistently remain above 50°F during the critical 7-day curing period. Late summer and early fall often provide the best combination of favorable weather and competitive contractor pricing. Winter installations are possible but require cold-weather techniques that add 10-20% to costs.

How thick should a residential sidewalk be?

Standard residential sidewalks should be 4 inches thick minimum. Properties that may see occasional vehicle traffic (riding mowers, golf carts) benefit from 5-inch thickness. Commercial sidewalks or those in heavy-traffic areas should be 5-6 inches thick. Thicker concrete costs more initially but dramatically improves durability and lifespan.

Can I pour my own concrete sidewalk to save money?

While DIY sidewalk installation is possible for experienced homeowners, it’s challenging and risky. Proper excavation, base preparation, forming, concrete placement, and finishing require specialized knowledge and equipment. Mistakes result in premature failure requiring complete replacement—often costing more than hiring professionals initially. Additionally, DIY work may not meet City of Lawrence code requirements or pass inspections.

Making Your Sidewalk Investment Count

Understanding concrete sidewalk installation costs in Lawrence, KS empowers you to make informed decisions that balance budget with quality. While prices ranging from $8-$12 per square foot represent significant investment, a professionally installed concrete sidewalk delivers decades of reliable service with minimal maintenance.

The key to maximizing value lies in choosing experienced contractors who understand Lawrence’s specific challenges: clay soils requiring proper base preparation, municipal codes governing installation, and climate conditions affecting long-term performance. We’ve seen too many sidewalks fail prematurely because homeowners prioritized lowest price over proven quality.

When planning your sidewalk project, focus on these priorities: verify contractor credentials and references, insist on detailed quotes specifying materials and methods, ensure proper permits are obtained, and demand quality base preparation and drainage design. These fundamentals determine whether your sidewalk serves your property reliably for 30-50 years or requires expensive repairs within five years.

Whether you’re connecting your home to existing city sidewalks near downtown Lawrence, creating accessible pathways in West Lawrence subdivisions, or improving property access in East Lawrence neighborhoods, professional concrete installation delivers lasting value that enhances safety, accessibility, and curb appeal.

Sources and References

- City of Lawrence, Kansas – Planning and Development Services: https://lawrenceks.gov/

- Portland Cement Association – Concrete Fundamentals: https://www.cement.org/

- University of Kansas Campus Information: https://ku.edu/

Disclaimer: Pricing information represents average costs in Lawrence, KS as of December 2025 and may vary based on specific project requirements, site conditions, contractor availability, and material costs. Always obtain multiple detailed quotes from licensed contractors for accurate project pricing. This content is for informational purposes only and does not constitute professional advice.