Last Updated: December 30, 2025

Are you tired of crumbling brick walkways that shift and settle with every Kansas freeze-thaw cycle? Many Lawrence homeowners face a dilemma: preserve the historic charm of their neighborhoods while addressing safety and maintenance concerns. Stamped concrete walkways offer an elegant solution—combining the aesthetic appeal of traditional brick with modern durability and lower maintenance requirements.

As Lawrence, KS continues to balance historic preservation with practical infrastructure needs, stamped concrete walkways Lawrence KS have emerged as a popular alternative for homeowners in East Lawrence, Victorian neighborhoods, and areas near the KU campus. This technique allows you to replicate the look of brick, natural stone, or custom patterns while avoiding the common pitfalls of traditional materials—all at a competitive price point that makes sense for 2025 budgets.

Quick Answer: What Are Stamped Concrete Walkways?

Stamped concrete walkways use specialized stamps pressed into fresh concrete to create patterns mimicking brick, stone, or tile. This technique costs minimally more than standard concrete but delivers the aesthetic appeal of premium materials without the maintenance headaches of authentic brick sidewalks common in Lawrence’s historic districts.

Key Benefits for Lawrence Homeowners:

- Replicates historic brick appearance while meeting modern safety standards

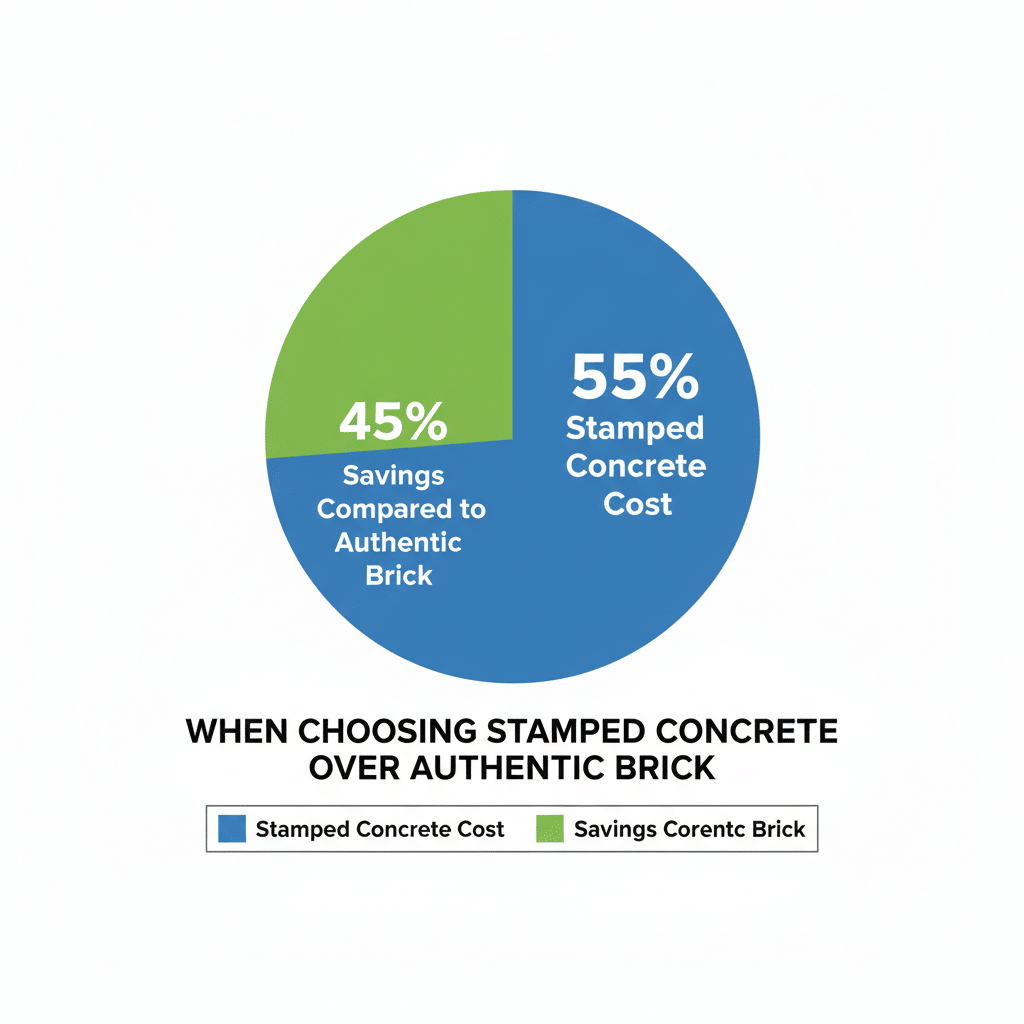

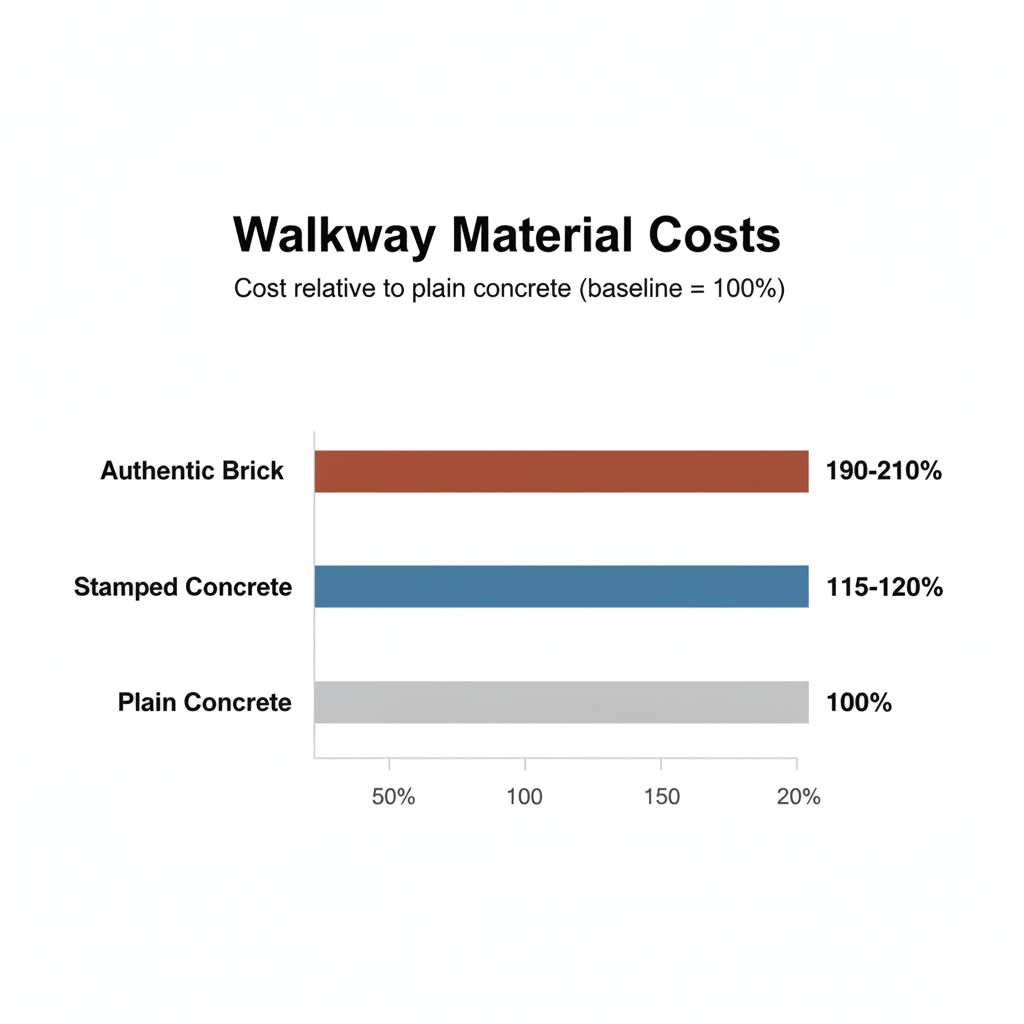

- Costs approximately 15-20% more than plain concrete but 40-50% less than authentic brick installation

- Withstands Kansas freeze-thaw cycles better than segmented brick paths

- Requires minimal maintenance compared to traditional materials

- Customizable patterns and colors to match neighborhood character

- Typically installed in 2-3 days for standard residential walkways

Understanding Stamped Concrete for Lawrence Properties

Stamped concrete walkways have gained significant traction in Lawrence, particularly following the 2024 City of Lawrence Brick Open House discussions about sidewalk priorities. As a concrete contractor working throughout zip codes 66044, 66046, and 66049, we’ve seen growing interest from homeowners who want to honor Lawrence’s historic character without inheriting the repair burdens of century-old brick paths.

How Stamped Concrete Works

The stamping process begins with standard concrete preparation—excavation, base material, and proper grading. Before the concrete hardens, contractors apply color hardeners and release agents, then press specialized rubber or polyurethane stamps into the surface. These stamps create textures and patterns that faithfully replicate brick, cobblestone, slate, or custom designs.

According to Portland Cement Association, stamped concrete requires the same labor and materials as conventional concrete, with only the stamping tools and coloring agents adding incremental cost. This makes it an economically attractive option for Lawrence homeowners seeking aesthetic upgrades without breaking the budget.

Why Lawrence Homeowners Choose Stamped Concrete

Lawrence’s historic neighborhoods—particularly areas near Ninth and Rhode Island streets where the 2018 East Ninth Street reconstruction unearthed thousands of original bricks—face unique challenges. Traditional brick sidewalks shift with ground movement, create tripping hazards, and require frequent small-scale repairs. While residents value brick’s aesthetic contribution to Lawrence’s “unmistakable character,” the practical concerns are real.

Stamped concrete walkways in Lawrence, KS address this tension by offering visual continuity with historic districts while providing a stable, ADA-compliant walking surface. When our team works in East Lawrence, we regularly consult with homeowners who appreciate brick’s charm but need solutions that won’t require repair every few years as Kansas weather takes its toll.

Climate Considerations for Northeast Kansas

Kansas experiences dramatic temperature swings and moisture fluctuations that challenge concrete durability. Due to Lawrence’s freeze-thaw cycles—typically 50-70 annually—we always specify air-entrained concrete for walkway projects. This concrete contains microscopic air bubbles that provide expansion space when water freezes, preventing cracking and spalling that would otherwise occur within 3-5 years.

Before any excavation work, we coordinate with Evergy and Kansas Gas Service to mark underground utilities—a critical step given the concentration of aging infrastructure in Lawrence’s older neighborhoods. This preparation prevents costly delays and ensures safety throughout the installation process.

Common Mistakes When Planning Stamped Concrete Walkways

Even experienced homeowners make critical errors when planning walkway projects. Understanding these pitfalls helps ensure your investment delivers lasting value and visual appeal.

Choosing Patterns That Don’t Match Neighborhood Context

One frequent mistake involves selecting stamp patterns or colors that clash with surrounding properties. In East Lawrence’s Victorian neighborhoods, running bond brick patterns and earthy red tones complement historic architecture. A sleek ashlar slate pattern might look stunning in a modern development but appears out of place near homes built in the 1890s.

We recommend walking your block and photographing existing materials before finalizing design choices. This simple step ensures your concrete walkway enhances rather than disrupts your neighborhood’s aesthetic continuity.

Inadequate Base Preparation

Kansas clay soil expands and contracts with moisture changes, creating movement that cracks inadequately supported concrete. Some contractors skimp on base material to reduce costs—a decision that leads to settlement, cracking, and premature failure. Proper preparation requires 4-6 inches of compacted aggregate base, particularly in areas with poor drainage or expansive clay soils common throughout Douglas County.

Overlooking Maintenance Requirements

While stamped concrete requires less maintenance than brick, it’s not maintenance-free. Homeowners who skip resealing every 2-3 years experience accelerated color fading and surface deterioration. The sealer protects against moisture penetration, UV damage, and freeze-thaw damage—particularly important given Lawrence’s climate extremes. Our maintenance guide for stamped concrete covers best practices for long-term preservation.

Best Approach to Planning Your Stamped Concrete Walkway

Successful walkway projects begin with thorough planning that considers design, functionality, budget, and local regulations. Here’s how to approach your project systematically.

Design Selection for Historic Compatibility

Lawrence’s historic districts benefit from stamp patterns that echo traditional materials. Running bond brick patterns remain the most popular choice for properties near downtown and in East Lawrence, closely replicating the original brick sidewalks that define these areas. For Victorian-era homes, consider adding decorative borders or bands that reference period architectural details.

Color selection matters equally. We typically recommend color palettes that match or complement existing brick on the property—often warm reds, browns, or sandy tones that harmonize with Lawrence’s architectural heritage. Avoid overly bright or artificial-looking colors that draw attention rather than blending naturally with the surroundings.

Understanding Local Requirements

The City of Lawrence has specific requirements for sidewalk installation, particularly in historic districts and areas near registered structures. Homeowners should verify whether their property falls within a historic overlay district, which may require review by the Historic Resources Commission before making exterior changes visible from the street.

Additionally, Lawrence building codes specify minimum walkway widths (typically 4 feet for front walkways), slope requirements for drainage, and accessibility standards. When we work with clients throughout the 66046 and 66049 areas, we ensure projects meet these standards from the outset, preventing costly modifications later.

Timing Your Project

Kansas weather significantly impacts concrete installation. Optimal installation occurs when temperatures remain consistently between 50-85°F—typically late April through May and September through mid-October. Avoid summer’s extreme heat, which causes rapid surface drying and potential cracking, and winter’s freezing temperatures, which prevent proper curing.

Spring scheduling offers the added benefit of enjoying your new walkway throughout summer and fall. However, this popular window fills quickly, so contact contractors 6-8 weeks ahead to secure your preferred installation date.

Step-by-Step Installation Process

Understanding the installation process helps set realistic expectations for timeline, disruption, and final results. Here’s what happens during a typical stamped concrete walkway project in Lawrence.

Preparation and Excavation (Day 1)

Installation begins with marking the walkway layout and verifying utility locations. We excavate to the appropriate depth—typically 8-10 inches total—to accommodate base material and concrete thickness. For a standard 4-foot-wide walkway running 25 feet from street to front steps, excavation takes 3-4 hours.

Next comes base preparation: 4-6 inches of compacted crushed limestone or road base, graded to ensure proper drainage away from the home’s foundation. This step proves critical for longevity, particularly in Lawrence’s clay soils that retain moisture and expand. We use plate compactors to achieve 95% compaction density, creating a stable platform that resists settlement.

Concrete Placement and Stamping (Day 2)

Concrete delivery and placement occur on installation day. For walkways, we specify 4 inches of 4,000 PSI air-entrained concrete with fiber reinforcement—a mixture engineered to handle freeze-thaw cycles and foot traffic for decades. Immediately after placement and initial smoothing, crews apply color hardener (if using integral color plus surface hardener) and release agent.

The stamping process requires speed and precision. Once concrete reaches the right consistency—firm enough to hold the pattern but soft enough to accept the stamp—crews press stamp mats into the surface, creating the desired texture and pattern. This window lasts just 2-4 hours, requiring experienced crews to complete the work before the concrete hardens further.

Curing and Sealing (Days 3-10)

After stamping, concrete needs time to cure and develop full strength. We apply curing compound and restrict foot traffic for 24-48 hours. Full cure takes 28 days, though light foot traffic can resume after 3-5 days.

Sealing typically occurs 7-14 days after installation, once the concrete has cured sufficiently but before exposure to weather and traffic causes surface wear. We use solvent-based acrylic sealers for their UV resistance and ability to enhance color depth—particularly important for maintaining the authentic brick appearance Lawrence homeowners desire.

Cost Factors for Stamped Concrete Walkways in Lawrence

As of December 2025, stamped concrete walkways in Lawrence, KS typically range from $12-18 per square foot installed, depending on pattern complexity, site conditions, and project size. This pricing includes all preparation, materials, labor, and initial sealing.

| Project Size | Typical Cost Range | Notes |

|---|---|---|

| Small walkway (50 sq ft) | $850-$1,100 | Higher per-sq-ft cost due to setup/mobilization |

| Standard walkway (100 sq ft) | $1,400-$1,800 | Most common residential size |

| Large walkway (200 sq ft) | $2,600-$3,400 | Better economy of scale |

| Plain concrete (comparison) | $8-$12 per sq ft | Basic finish, no decorative elements |

| Authentic brick installation | $22-$30 per sq ft | Material and labor-intensive |

Several factors influence final pricing. Complex patterns with multiple colors or custom designs add 15-25% to base costs. Difficult site access—common in older Lawrence neighborhoods with mature trees and narrow lot lines—may increase labor costs. Extensive excavation due to poor drainage or existing material removal also affects total investment.

For context, a standard 600-square-foot stamped concrete patio installation runs approximately $6,000-$7,200 in the Lawrence market. More details on pricing factors appear in our comprehensive cost guide for 2025.

Comparing Value: Stamped vs. Traditional Materials

Initial cost represents just one component of total ownership expense. When we discuss options with homeowners in the 66044 zip code, we emphasize lifecycle costs that include maintenance, repairs, and eventual replacement.

Authentic brick sidewalks require periodic releveling as individual bricks shift, joint sand replenishment, and occasional brick replacement. Over a 20-year period, these maintenance costs can equal or exceed the initial installation premium. Stamped concrete, by contrast, needs only resealing every 2-3 years at $1-2 per square foot—dramatically lower long-term maintenance investment.

Frequently Asked Questions

How long do stamped concrete walkways last in Lawrence’s climate?

With proper installation using air-entrained concrete and regular maintenance including resealing every 2-3 years, stamped concrete walkways typically last 25-30 years in northeast Kansas. The key factors determining longevity include proper base preparation, adequate concrete thickness (minimum 4 inches), and protection from freeze-thaw damage through appropriate concrete mix design and surface sealing.

Can stamped concrete match the exact appearance of Lawrence’s historic brick sidewalks?

Modern stamping techniques create remarkably authentic brick replicas, including variations in color, texture, and even slight irregularities that characterize aged materials. While close inspection reveals differences, the overall visual effect from normal viewing distances convincingly mimics historic brick. Many homeowners and visitors cannot distinguish well-executed stamped concrete from authentic brick without close examination.

What maintenance does stamped concrete require?

Stamped concrete maintenance involves regular cleaning with mild soap and water, prompt removal of stains, and resealing every 2-3 years. Lawrence homeowners should also ensure proper drainage to prevent water pooling and ice formation during winter months. Compared to brick walkways that require joint sand replenishment, releveling, and individual brick replacement, stamped concrete demands significantly less ongoing attention.

Are permits required for walkway installation in Lawrence?

Requirements vary by project scope and location. Simple walkway replacements following existing footprints typically don’t require permits, but projects that alter drainage patterns, encroach on easements, or occur within historic districts may need city review. We recommend contacting the City of Lawrence Development Services department or consulting with your concrete contractor to verify requirements for your specific situation.

How does stamped concrete perform in icy conditions?

Stamped concrete provides better traction than smooth finished concrete due to its textured surface, though it’s not as slip-resistant as broom-finished concrete. Salt and chemical deicers can damage the sealer and surface if used excessively, so we recommend using sand or safer ice-melting products specifically formulated for decorative concrete. The solid, level surface of stamped concrete does facilitate easier snow removal compared to uneven brick paths.

Choosing the Right Contractor for Your Project

Stamped concrete installation requires specialized skills beyond standard concrete work. The narrow window for stamping demands experience, proper tools, and efficient crews. When evaluating contractors for your Lawrence walkway project, consider these critical factors:

Portfolio review: Ask to see completed projects, particularly those in Lawrence neighborhoods similar to yours. Photos should show close-up pattern detail and overall project context. If possible, drive by completed projects to assess how well the stamped concrete has weathered Kansas conditions.

References: Speak with previous clients about their experience, particularly regarding timeline adherence, communication, and how the walkway has performed over time. Lawrence homeowners who have lived through at least one full winter can provide valuable insights into durability and weather resistance.

Warranty coverage: Reputable contractors stand behind their work with warranties covering workmanship defects. Typical warranties range from 1-3 years, though they exclude damage from improper maintenance, ground movement, or acts of nature. Understand exactly what’s covered before signing contracts.

Local options for stamped concrete work in Lawrence include Lawrence Concrete Pros and several other established contractors serving Douglas County. Taking time to evaluate options ensures your investment delivers the quality and longevity you expect.

Conclusion: Balancing Heritage with Practicality

Stamped concrete walkways represent an intelligent compromise for Lawrence homeowners who value historic character but need modern durability and manageable maintenance. As the city continues conversations about preserving brick sidewalks in historic districts, stamped concrete offers a middle path—honoring aesthetic traditions while addressing practical concerns about safety, accessibility, and long-term costs.

Whether you’re replacing a deteriorating brick path in East Lawrence, installing a new walkway in a Victorian neighborhood, or simply updating your home’s curb appeal, stamped concrete delivers authentic appearance with superior performance. The 15-20% premium over plain concrete buys you visual richness that complements Lawrence’s architectural heritage while the solid, monolithic surface provides stability that segmented brick cannot match.

As we close out 2025, material costs have stabilized and experienced contractors have capacity for early 2026 projects. Now is an excellent time to begin planning your walkway upgrade, positioning your project for spring installation when weather conditions optimize results. Your investment will enhance your property’s appearance, improve safety and accessibility, and contribute to the ongoing evolution of Lawrence’s streetscape—preserving historic character through modern techniques.

Sources and References

- Portland Cement Association – Decorative Concrete Technology and Applications

- City of Lawrence, Kansas – Historic Preservation Guidelines and Development Services

- Douglas County, Kansas – Property Records and Historic Documentation

- National Weather Service – Northeast Kansas Climate Data