Last Updated: December 31, 2025

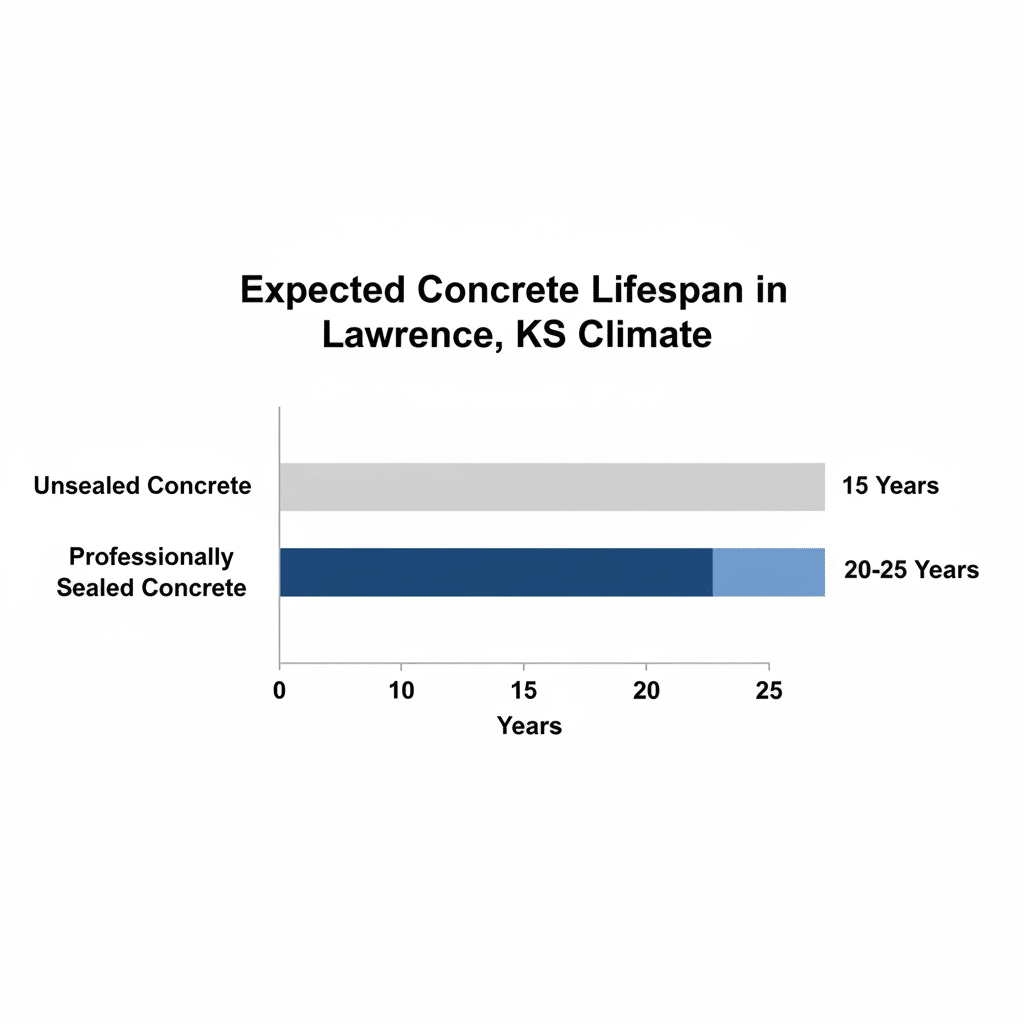

Is your concrete driveway showing signs of wear after just a few Kansas winters? Many Lawrence property owners discover too late that unsealed concrete deteriorates rapidly under freeze-thaw cycles, leading to costly replacements. Professional concrete sealing services in Lawrence, KS can extend the lifespan of your concrete surfaces by 5-10 years while enhancing their appearance and protecting your investment.

With Lawrence’s variable climate—from humid summers to freezing winters—concrete faces unique environmental stresses. Whether you’re protecting a historic home in Old West Lawrence or maintaining commercial property near the intersection of Massachusetts Street and 6th Street, proper sealing makes the difference between concrete that lasts decades and surfaces that require premature replacement. We’ll explore why sealing matters, what the process involves, and how to choose the right protection for your specific needs.

Quick Answer: What Are Concrete Sealing Services?

Concrete sealing services involve applying protective coatings to concrete surfaces that prevent water intrusion, resist staining, and protect against weathering. Professional sealers clean, prepare, and apply specialized products that penetrate or coat the concrete surface, creating a barrier against moisture, chemicals, and UV damage while enhancing appearance.

Key Takeaways:

- Sealing extends concrete lifespan by preventing water damage and freeze-thaw deterioration

- Professional application ensures proper surface preparation and product selection

- Different sealer types suit different applications—driveways, patios, and commercial surfaces require specific formulations

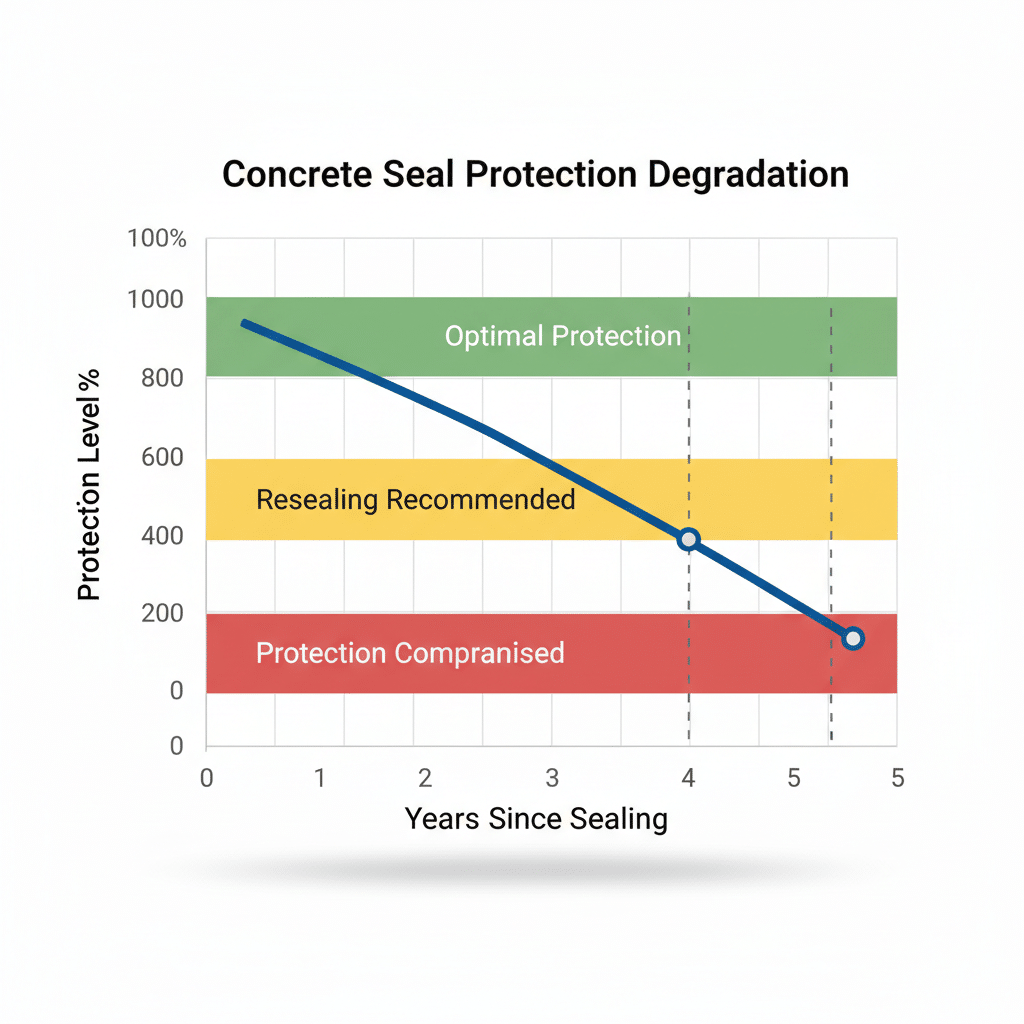

- Resealing every 2-5 years maintains protection and appearance

- Kansas climate conditions make sealing particularly important for preventing moisture damage

Why Concrete Sealing Matters in Lawrence, KS

When our team works throughout Lawrence neighborhoods like Oread, Sunset Hill, and North Lawrence, we consistently see the same pattern: unsealed concrete fails prematurely. Kansas weather creates a perfect storm for concrete deterioration. Winter freeze-thaw cycles cause water trapped in concrete pores to expand, creating microcracks that compound over time. Summer heat and humidity accelerate surface degradation and staining.

The Federal Highway Administration documents how moisture intrusion represents the primary cause of concrete failure. In Lawrence’s climate, this becomes particularly problematic. During winter months, water penetrates unsealed concrete, freezes, expands by approximately 9%, and creates internal pressure exceeding concrete’s tensile strength. This cycle repeats dozens of times each winter, progressively damaging the structure.

Climate-Specific Challenges for Kansas Concrete

Due to Kansas freeze-thaw cycles, we always recommend air-entrained concrete with proper sealing for any exterior application. Lawrence experiences an average of 110 freeze-thaw cycles annually—significantly higher than many regions. This means unsealed concrete faces over 100 opportunities for water damage each year.

Before undertaking any concrete work in areas served by Evergy or Kansas Gas Service, coordination ensures underground utilities remain protected. Once concrete is poured and cured, sealing becomes the final critical step in long-term protection. We serve homeowners throughout Lawrence, including zip codes 66044, 66046, and 66049, where property owners increasingly recognize sealing as essential maintenance rather than optional enhancement.

Protection Beyond Weather: Stains, Chemicals, and Wear

Sealing protects against more than just weather. Driveways face automotive fluids—oil, transmission fluid, brake fluid—that penetrate unsealed concrete and leave permanent stains. Road salts and de-icing chemicals accelerate surface scaling. Patios encounter food spills, beverage stains, and organic matter that discolor surfaces.

Commercial properties near the University of Kansas campus experience particularly high foot traffic. Sealed concrete resists abrasion wear while maintaining a professional appearance. For property managers overseeing facilities in the 66045 area, sealing represents cost-effective maintenance that delays expensive replacement projects. Learn more about protecting your investment with our guide on concrete driveway maintenance tips for Lawrence homeowners.

Common Mistakes Property Owners Make with Concrete Sealing

We encounter numerous misconceptions when discussing concrete sealing services in Lawrence, KS with property owners. Understanding these common mistakes helps you make informed decisions and avoid costly errors that compromise protection or waste money on ineffective treatments.

Applying Sealer to New Concrete Too Soon

The most frequent error involves sealing concrete before it’s fully cured. Concrete continues curing for 28 days after pouring, releasing moisture during this process. Applying sealer prematurely traps moisture inside, preventing proper curing and potentially causing discoloration, bubbling, or delamination. Professional contractors know that patience during this curing period ensures optimal sealer adhesion and performance.

For existing concrete requiring resealing, timing matters differently. Our experience working with Lawrence residents shows that late spring or early fall provides ideal conditions—temperatures between 50°F and 90°F with low humidity and no rain forecasted for 24-48 hours after application.

Choosing the Wrong Sealer Type

Not all sealers suit all applications. Penetrating sealers work differently than topical sealers, and using the wrong type undermines protection. Penetrating sealers chemically react with concrete, filling pores without creating a surface film. They’re ideal for driveways and high-traffic areas where traction matters. Topical sealers create a protective surface layer, offering enhanced appearance and stain resistance but potentially reducing slip resistance when wet.

For decorative stamped concrete—common in Lawrence patios—topical sealers enhance color and pattern definition. The wrong choice diminishes the visual investment you’ve made. Our guide on maintaining stamped concrete patios in Lawrence, KS provides detailed information on proper sealer selection for decorative applications.

Inadequate Surface Preparation

DIY sealing often fails because homeowners underestimate preparation requirements. Concrete must be thoroughly cleaned, with all stains, efflorescence, previous sealer residue, and contaminants removed. Oil stains require specialized degreasers. Efflorescence (white crystalline deposits) needs acid etching or mechanical removal. Existing failed sealer must be stripped completely.

Professional services include pressure washing at appropriate PSI levels—too low leaves contaminants, too high damages surface texture. We source materials from local suppliers familiar with Lawrence building codes and concrete characteristics typical of this region, ensuring compatibility between preparation methods and sealer products.

Professional Sealing Process: What to Expect

Understanding the professional sealing process helps property owners recognize quality service and set realistic expectations. Reputable contractors follow systematic procedures that ensure long-lasting protection and optimal appearance.

Initial Assessment and Surface Evaluation

Professional concrete sealing begins with thorough assessment. Contractors evaluate concrete condition, identifying cracks, spalling, or damage requiring expert concrete repair before sealing. Previous sealer presence affects preparation requirements—some surfaces need complete stripping while others require only cleaning.

Moisture testing determines whether concrete is sufficiently dry for sealing. According to American Concrete Institute standards, concrete moisture content must fall below specific thresholds depending on sealer type. Professional contractors use moisture meters to verify readiness rather than guessing based on age or appearance.

Cleaning, Repair, and Preparation

Preparation determines sealing success. This phase includes:

- Pressure washing: Removes dirt, debris, organic growth, and loose material

- Stain treatment: Applies specialized cleaners for oil, rust, or organic stains

- Crack repair: Fills and seals cracks to prevent moisture intrusion

- Efflorescence removal: Eliminates mineral deposits that interfere with sealer adhesion

- Drying time: Allows complete moisture evaporation before sealer application

For pool decks and specialized applications, contractors may recommend specific preparation techniques. Our swimming pool deck services include preparation tailored to high-moisture environments where proper sealing prevents slip hazards and surface deterioration.

Sealer Application and Curing

Application methods vary by sealer type. Penetrating sealers typically require sprayer application with sufficient product to saturate the surface, followed by removal of excess before it dries. Topical sealers may be sprayed or rolled, often requiring two thin coats rather than one thick application to avoid puddling, bubbling, or uneven appearance.

Professional contractors control application rate, overlap patterns, and drying conditions. Weather monitoring ensures application occurs under ideal conditions—a contrarian insight many national providers miss is that Kansas wind patterns affect sealer drying rates significantly, requiring experienced contractors to adjust application timing and techniques based on local conditions rather than generic manufacturer guidelines.

Curing time before traffic exposure depends on sealer chemistry—typically 24-48 hours for foot traffic and 72 hours for vehicles. Professional services include clear communication about when surfaces become usable again.

Types of Concrete Sealers and Their Applications

Selecting appropriate sealer chemistry determines protection effectiveness and longevity. Different formulations serve different purposes, and professional contractors match products to specific applications and property owner priorities.

| Sealer Type | Best Applications | Longevity |

|---|---|---|

| Penetrating Silane/Siloxane | Driveways, walkways, exposed aggregate | 5-10 years |

| Acrylic Topical | Decorative concrete, stamped patios | 1-3 years |

| Epoxy | Garage floors, commercial spaces | 3-7 years |

| Polyurethane | High-traffic commercial, industrial | 5-10 years |

Penetrating sealers offer the longest protection with minimal appearance change—ideal for property owners prioritizing function over aesthetics. These products work by chemically reacting within concrete pores, creating hydrophobic barriers that repel water while allowing vapor transmission. This breathability prevents moisture from becoming trapped, which is particularly important for Lawrence’s humid summers.

Topical sealers create visible surface enhancement—adding gloss or satin sheen while intensifying color. They provide excellent stain resistance and are preferred for decorative applications where appearance matters. However, they require more frequent reapplication and may need refreshing every 2-3 years depending on traffic and weather exposure.

Cost Factors for Concrete Sealing in Lawrence, KS

Investment in professional sealing varies based on multiple factors. Understanding pricing components helps property owners budget appropriately and recognize value versus cutting corners that compromise results.

Surface Area and Condition

Square footage represents the primary cost driver. Professional concrete sealing services in Lawrence, KS typically range from $0.50 to $3.00 per square foot depending on sealer type, surface condition, and preparation requirements. A standard 600-square-foot driveway might cost $300-$1,800 for sealing, compared to approximately $6,000 for complete replacement—making sealing a cost-effective protection strategy.

Surface condition significantly impacts pricing. Heavily stained or damaged concrete requiring extensive preparation increases labor costs. Conversely, well-maintained concrete needing only cleaning and sealing remains at the lower end of pricing ranges.

Sealer Quality and Type

Product quality varies dramatically. Professional-grade penetrating sealers cost more than basic acrylics but last significantly longer—often providing better value over time. High-performance polyurethanes represent premium options for demanding applications where durability justifies higher initial investment.

When evaluating quotes, consider total cost of ownership rather than just initial price. A $500 sealing job lasting 2 years costs more annually than a $1,200 application lasting 7 years. Professional contractors provide transparent guidance on expected longevity for different product options.

Maintaining Sealed Concrete for Maximum Longevity

Sealing provides protection, but ongoing maintenance extends that protection and maximizes your investment. Simple practices preserve appearance and performance while delaying resealing needs.

Regular cleaning removes dirt and debris before they cause staining or abrasion. Sweep or blow driveways weekly, and wash with mild detergent and water quarterly. Avoid harsh chemicals or de-icing salts that degrade sealers prematurely. For comprehensive maintenance strategies, refer to our winter concrete care guide covering protection during Kansas’s harsh cold months.

Address spills immediately—automotive fluids, food, and beverages can stain even sealed concrete if left to sit. Inspect sealed surfaces annually for wear patterns, particularly in high-traffic areas. Early resealing of worn spots prevents moisture intrusion and extends overall sealer life.

Frequently Asked Questions About Concrete Sealing

How often should concrete be resealed in Kansas?

Resealing frequency depends on sealer type and exposure conditions. Penetrating sealers typically last 5-10 years, while topical sealers require reapplication every 2-3 years. Kansas’s climate accelerates wear, so inspect annually and reseal when water no longer beads on the surface.

Can I seal concrete myself or should I hire professionals?

DIY sealing is possible for small, uncomplicated projects if you follow proper preparation procedures and product instructions. However, professional services ensure appropriate product selection, thorough preparation, and correct application techniques—factors that significantly impact longevity and appearance. For large areas or valuable decorative concrete, professional application justifies the investment.

What’s the best time of year to seal concrete in Lawrence?

Late spring (May) and early fall (September-October) provide ideal conditions—moderate temperatures, low humidity, and stable weather patterns. Avoid sealing during temperature extremes, high humidity, or when rain is forecasted within 24-48 hours of application.

Will sealing change my concrete’s appearance?

Appearance change depends on sealer type. Penetrating sealers cause minimal visible change—concrete may appear slightly darker when wet but returns to natural appearance when dry. Topical sealers create noticeable sheen (gloss or satin) and can deepen color intensity. Discuss appearance preferences with contractors to select appropriate products.

Does sealed concrete become slippery when wet?

Penetrating sealers don’t affect traction. Some topical sealers can reduce slip resistance when wet, particularly high-gloss formulations. For areas where slip resistance matters—pool decks, walkways, ramps—contractors recommend textured surfaces or sealers with anti-slip additives.

Protecting Your Concrete Investment

Professional concrete sealing services in Lawrence, KS represent smart preventive maintenance that extends surface lifespan, maintains appearance, and protects your property investment. Whether you’re preserving a historic driveway in Old West Lawrence or protecting commercial surfaces near downtown, proper sealing provides cost-effective insurance against Kansas’s challenging climate conditions.

Quality sealing begins with thorough assessment, proper preparation, and appropriate product selection—factors best ensured through professional contractors with local expertise. Lawrence Concrete Pros, along with other experienced providers in the area, offer the specialized knowledge needed to navigate Kansas-specific challenges and deliver lasting protection.

Don’t wait until damage occurs. Proactive sealing costs far less than reactive repairs or premature replacement. Contact qualified contractors to assess your concrete and develop a protection strategy tailored to your specific surfaces, usage patterns, and budget. Your concrete investment deserves professional-grade protection that extends its service life and maintains its appearance for years to come.

Sources and References

- Federal Highway Administration – Concrete Pavement Preservation Guide

- American Concrete Institute – Concrete Construction Standards

- Douglas County, Kansas – Building and Development Regulations

Disclaimer: This article provides general information about concrete sealing services. Specific recommendations should be based on professional assessment of your particular concrete surfaces and conditions. Pricing estimates are approximate and vary based on project specifics. Always obtain detailed quotes from licensed contractors before proceeding with work.