Last Updated: December 29, 2025

Is your concrete driveway showing its age with cracks, stains, and settling? Before you commit to a complete replacement, consider concrete driveway resurfacing in Lawrence, KS—a proven method that can extend your pavement’s life by 20 years or more at a fraction of the cost. With Lawrence’s historic concrete legacy dating back over a century and modern techniques that address Kansas’s challenging freeze-thaw cycles, resurfacing offers homeowners an effective solution to restore both durability and curb appeal.

For Lawrence residents in neighborhoods like Old West Lawrence, where concrete driveways are part of the area’s architectural heritage, resurfacing must balance modern performance standards with historic preservation requirements. Understanding the process, costs, and local regulations ensures your project meets City Code Chapter 16 specifications while delivering lasting results that withstand Kansas weather extremes.

Quick Answer: What Is Concrete Driveway Resurfacing?

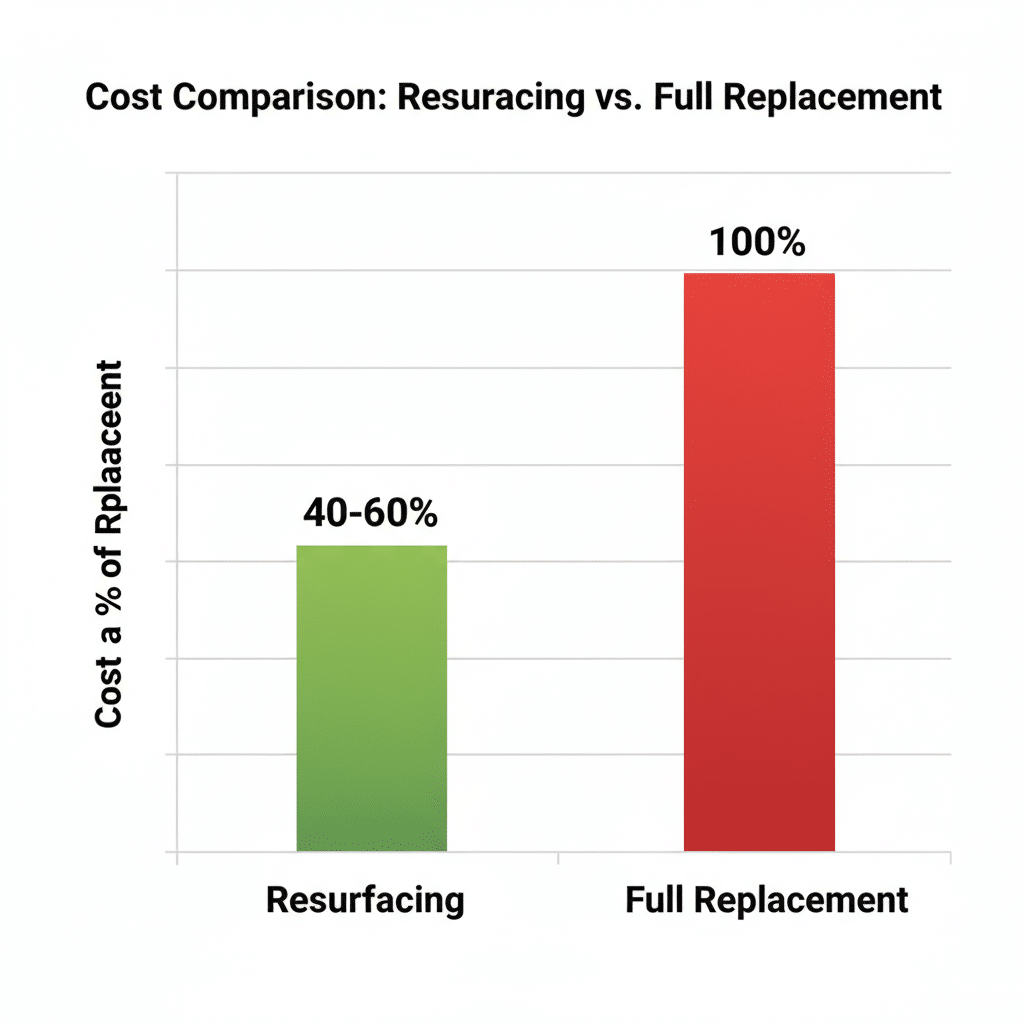

Concrete driveway resurfacing involves applying a new layer of Portland cement concrete (typically 4-5 inches thick) over your existing driveway to restore structural integrity and appearance. This method costs 40-60% less than full replacement and can extend your driveway’s service life by 20+ years when properly designed and installed according to Lawrence building codes.

Key Takeaways:

- Standard thickness: 4 inches minimum with welded wire fabric reinforcement (6×6 W2.9xW2.9)

- Expected lifespan: 20+ years with proper maintenance

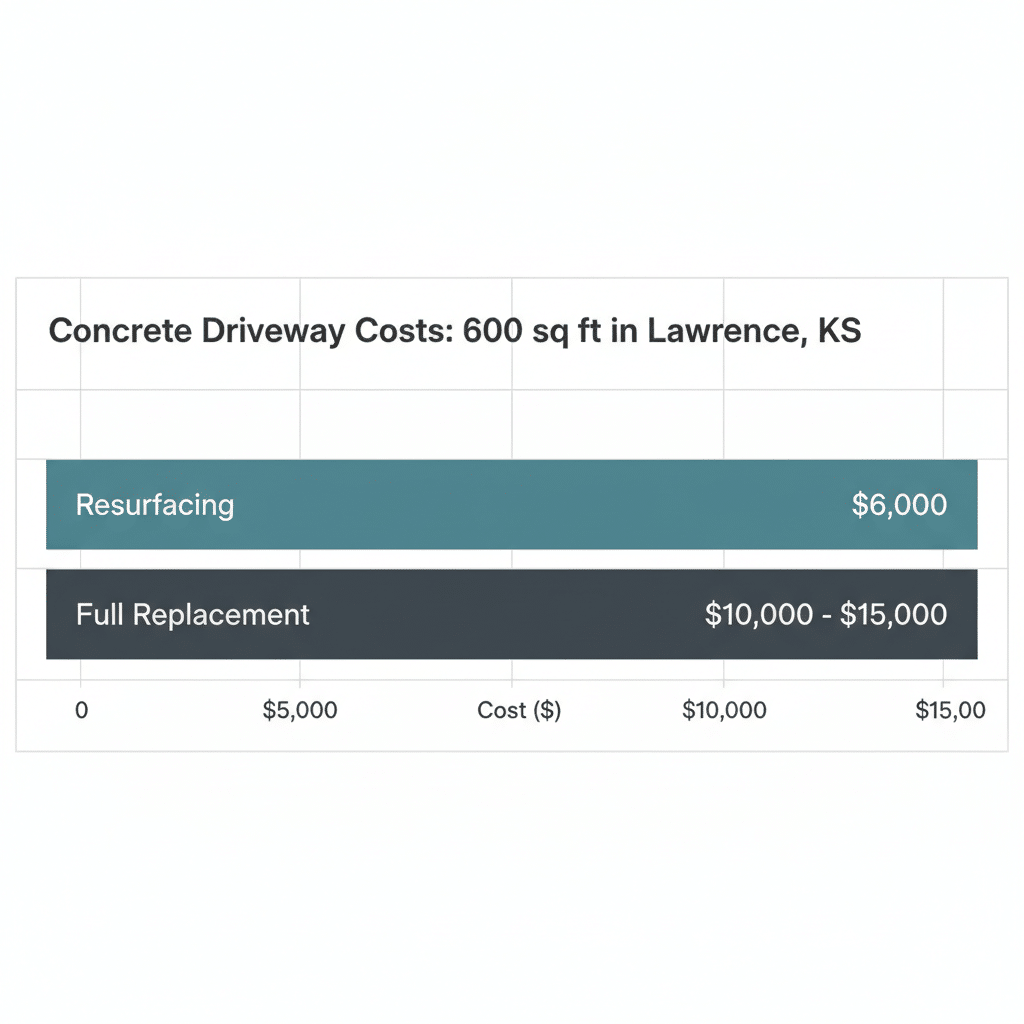

- Cost advantage: Approximately $6,000 for a 600 sq ft driveway versus higher replacement costs

- Historic district consideration: Requires Historic Resources Commission approval in designated areas

- Best for: Driveways with surface damage but structurally sound bases

Understanding Concrete Resurfacing in Lawrence’s Climate

When we work on concrete driveway resurfacing projects throughout Lawrence, KS, from Massachusetts Street down to Clinton Parkway, we’ve learned that Kansas’s climate demands specific considerations that national contractors often overlook. The freeze-thaw cycles that characterize Lawrence winters create unique challenges for concrete longevity.

Why Kansas Climate Demands Air-Entrained Concrete

Due to Kansas freeze-thaw cycles, we always specify air-entrained concrete for resurfacing projects—a critical detail that prevents premature failure. Air-entrained concrete contains microscopic air bubbles that provide expansion space when moisture freezes within the concrete matrix. Without this feature, water expansion during freezing temperatures causes internal pressure that leads to spalling, cracking, and surface deterioration within just a few winters.

This specification becomes particularly important when resurfacing older driveways in neighborhoods around the intersection of Iowa Street and 15th Street, where original concrete may predate modern air-entrainment standards. The new surface layer must outperform the base to justify the investment.

Lawrence Building Code Requirements for Driveways

The City of Lawrence enforces specific standards through City Code Chapter 16 that govern concrete driveway work. Resurfacing projects must include 4 inches of reinforced Portland cement concrete with welded wire fabric (6×6 W2.9xW2.9) positioned 2 inches from the surface. These requirements ensure structural adequacy for vehicle loads while maintaining consistency across Lawrence’s neighborhoods.

Contractors remain responsible for any street repairs necessitated during work, and projects requiring driveway widening must use matching materials—meaning concrete driveways must receive concrete overlays, not asphalt patches. Before any excavation begins, coordination with Evergy for underground utility marking protects both workers and infrastructure, preventing costly service disruptions.

Historic District Considerations

Old West Lawrence and other historic districts require Historic Resources Commission approval for driveway alterations. This process ensures resurfacing projects preserve the architectural character that defines these neighborhoods. We’ve found that stamped concrete patterns can successfully replicate historical appearances while incorporating modern performance features, satisfying both preservation requirements and durability standards.

Common Mistakes That Compromise Resurfacing Projects

Even experienced homeowners make critical errors when planning driveway repair projects. Understanding these pitfalls prevents costly failures and ensures your investment delivers the expected 20-year service life.

Resurfacing Over Structurally Compromised Bases

The most common mistake involves applying new concrete over driveways with underlying structural problems. Resurfacing addresses surface deterioration—cracks, staining, minor spalling—but cannot compensate for base failure, severe settling, or extensive subsurface voids. When the foundation fails, the overlay follows, wasting your entire investment within months.

Professional assessment determines whether your driveway qualifies for resurfacing or requires full replacement. Signs that indicate base problems include progressive settling creating drainage issues, wide cracks (over 1/4 inch), or visible voids beneath slab edges. In these cases, techniques like PolyLevel injection may stabilize the base before resurfacing, or complete replacement may prove more cost-effective.

Inadequate Surface Preparation

Proper bonding between the existing concrete and new overlay depends entirely on surface preparation. Oil stains, sealers, dirt, and loose concrete prevent the chemical and mechanical bond necessary for long-term performance. We’ve observed failures where contractors skipped aggressive cleaning and profiling steps, resulting in delamination within the first year.

Successful preparation includes pressure washing at 3,000+ PSI, chemical degreasing for oil-contaminated areas, mechanical scarification to create surface texture, and acid etching to open concrete pores. This labor-intensive process consumes significant project time but determines whether your overlay lasts two years or twenty.

Ignoring Drainage Improvements

Resurfacing presents the ideal opportunity to correct drainage problems that contribute to concrete deterioration. Standing water accelerates freeze-thaw damage, promotes staining, and undermines edges. Projects that replicate existing drainage patterns perpetuate these issues, shortening the new surface’s lifespan unnecessarily.

Strategic overlay design can introduce proper slope (minimum 1/8 inch per foot toward drainage areas), redirect water away from foundation walls, and eliminate low spots. This proactive approach protects both your driveway investment and your home’s foundation from moisture intrusion.

Best Approaches for Long-Lasting Resurfacing Results

Successful concrete driveway resurfacing in Lawrence, KS requires matching the right technique to your specific conditions while adhering to local building standards and climate requirements.

Bonded Versus Unbonded Overlay Systems

Two primary resurfacing approaches serve different scenarios. Bonded overlays adhere directly to the prepared existing surface, typically 4-5 inches thick to minimize curling and warping tendencies. This method works best when the underlying concrete remains structurally sound with only surface deterioration, offering superior long-term performance for residential driveways throughout the 66044, 66046, and 66049 zip codes.

Unbonded overlays incorporate a separation layer—often bituminous material—between old and new concrete. This approach accommodates bases with existing crack patterns, reducing reflection cracking that would otherwise telegraph through the new surface. While thicker and more expensive, unbonded systems suit driveways with widespread but stable cracking where full removal isn’t economically justified.

| System Type | Thickness | Best Application | Expected Service Life |

|---|---|---|---|

| Bonded Overlay | 4-5 inches | Stable bases, surface damage only | 20+ years |

| Unbonded Overlay | Thicker with separation layer | Cracked bases, load capacity upgrades | 20+ years |

Decorative Options That Add Value

Modern resurfacing extends beyond functional repair to enhance curb appeal. Stamped concrete replicates the appearance of stone, brick, or slate while maintaining concrete’s durability and cost advantages. Color hardeners and stains customize the aesthetic to complement your home’s architecture—particularly valuable in historic neighborhoods where appearance standards apply.

Exposed aggregate finishes provide slip resistance and visual interest while performing well in Kansas weather. This option works especially effectively for driveways near the intersection of Bob Billings Parkway and Wakarusa Drive, where newer developments favor textured concrete surfaces that distinguish properties.

Timing Your Resurfacing Project

Concrete curing requires specific temperature and moisture conditions for optimal strength development. In Lawrence, optimal resurfacing windows occur during spring (April-May) and fall (September-October) when temperatures remain consistently between 50-85°F and precipitation risks decrease. Summer heat accelerates curing, requiring intensive moisture retention measures, while temperatures below 40°F demand heated enclosures and extended cure times that increase costs.

Planning your project for these ideal periods ensures the concrete achieves its full design strength while minimizing contractor scheduling premiums that accompany rush work during temperature extremes.

Step-by-Step Resurfacing Process

Understanding the resurfacing workflow helps homeowners recognize quality workmanship and set realistic expectations for project duration and disruption.

Initial Assessment and Preparation

Professional evaluation begins with structural assessment using concrete sounding (tapping to identify hollow areas), crack mapping, and drainage analysis. This inspection determines whether resurfacing suits your situation or if base stabilization or full replacement serves you better. Our team also reviews local permit requirements and schedules Historic Resources Commission review when necessary for properties in designated districts.

Surface preparation follows assessment, involving pressure washing to remove loose material and dirt, degreasing contaminated areas, mechanical scarification creating surface profile for bonding, and acid etching opening concrete pores. This phase typically requires 1-2 days depending on driveway size and condition.

Overlay Application and Finishing

Bonding agents applied immediately before concrete placement ensure adhesion between layers. The concrete mix—specified with air entrainment for freeze-thaw resistance—goes down in sections with control joints positioned to match underlying patterns or placed strategically to control cracking. Welded wire fabric reinforcement meets Code Chapter 16 requirements, positioned 2 inches from the finished surface.

Finishing techniques depend on your aesthetic goals. Standard broom finishes provide traction and suit functional driveways. Stamped patterns require specialized tools and timing to achieve realistic stone or brick textures. Color treatments integrate during or immediately after placement for permanent, fade-resistant results.

Curing and Protection

Proper curing determines whether your resurfaced driveway achieves its full 20-year potential or fails prematurely. Moisture retention through water spraying, wet burlap, or curing compounds maintains hydration necessary for cement hydration—the chemical reaction that creates concrete strength. This process continues for minimum seven days, though full strength development takes 28 days.

Vehicle access restrictions apply during this period: foot traffic after 24-48 hours, light vehicle traffic after 7 days, and full use after 14 days. Rushing these timelines risks permanent damage that resurfacing cannot fix.

Maintenance Strategies for Maximum Longevity

Resurfacing provides a fresh start, but proper maintenance determines whether your investment reaches its expected service life or requires premature repairs.

Seasonal Protection Measures

Kansas winters demand proactive concrete protection strategies. Avoid deicing chemicals containing ammonium sulfate or ammonium nitrate, which chemically attack concrete. Safer alternatives include calcium magnesium acetate or sand for traction without chemical damage. Remove snow promptly to prevent repeated freeze-thaw cycles in standing meltwater.

Spring cleaning removes accumulated winter debris and allows inspection for any damage requiring prompt attention. Fall preparation includes crack sealing before winter moisture penetration and application of penetrating sealers every 2-3 years to reduce water absorption without creating slippery surfaces.

Addressing Problems Early

Minor issues become major failures when ignored. Hairline cracks sealed within the first year prevent water intrusion and expansion. Surface staining responds to appropriate cleaning products—oil stains require degreasers, organic stains need oxidizing cleaners. Edge spalling caught early may need only localized repair rather than section replacement.

Annual professional inspections identify developing problems before they compromise structural integrity, extending your resurfaced driveway’s service life well beyond the 20-year baseline.

Frequently Asked Questions

How long does resurfaced concrete last in Lawrence’s climate?

Properly installed concrete overlays using air-entrained mixes and correct reinforcement achieve 20+ years of service life with routine maintenance. Kansas freeze-thaw cycles challenge concrete durability, making specification compliance and quality installation critical to reaching this expectation.

Can all concrete driveways be resurfaced?

No. Resurfacing requires a structurally sound base. Driveways with extensive settling, wide cracking patterns, or underlying voids need base stabilization or full replacement. Professional assessment determines your driveway’s candidacy for resurfacing versus other repair options.

What permits does Lawrence require for driveway resurfacing?

Standard resurfacing typically requires building permits through the City of Lawrence. Properties in historic districts need additional Historic Resources Commission approval before work begins. Your contractor should handle permit coordination as part of project management.

How does resurfacing cost compare to replacement?

Resurfacing costs approximately 40-60% less than complete replacement. A typical 600 square foot driveway resurfacing runs around $6,000, while full replacement with removal and disposal of existing concrete costs significantly more. The exact difference depends on base condition, access difficulty, and finish selections.

When is the best time to resurface a driveway in Lawrence?

Spring (April-May) and fall (September-October) provide optimal conditions with moderate temperatures between 50-85°F and lower precipitation probability. These windows allow proper curing without temperature-related complications that increase costs or compromise quality.

Making the Right Decision for Your Lawrence Driveway

Concrete driveway resurfacing in Lawrence, KS offers homeowners a cost-effective path to restore deteriorated driveways while adding decades of service life. The combination of modern overlay techniques, climate-appropriate specifications like air-entrained concrete, and compliance with local building codes creates durable results that justify the investment. Whether your property sits in Old West Lawrence’s historic district or newer developments near Clinton Parkway, resurfacing can address surface deterioration while preserving or enhancing your home’s curb appeal.

Success depends on honest assessment of your driveway’s base condition, proper surface preparation, quality materials specified for Kansas weather, and professional installation that meets City of Lawrence standards. The 20-year service life that properly executed resurfacing delivers makes it an attractive alternative to full replacement for driveways with surface problems but sound structural foundations.

Local options for professional concrete services include Lawrence Concrete Pros and other established contractors familiar with Lawrence’s specific requirements—from Historic Resources Commission procedures to coordination with Evergy for utility protection. Choosing experienced professionals ensures your project achieves both immediate aesthetic improvement and long-term durability.

As December 29, 2025 begins the planning season for spring construction, homeowners considering driveway improvements should schedule professional assessments early to secure optimal installation windows and avoid seasonal scheduling premiums.

Sources and References

- National Cooperative Highway Research Program (NCHRP) Synthesis 99 – Concrete Pavement Resurfacing Techniques

- City of Lawrence Municipal Code Chapter 16 – Building and Construction Standards

- U.S. Army Corps of Engineers – Post-WWII Concrete Rehabilitation Design Criteria

- Portland Cement – Historical development and modern applications

- Douglas County Historic Preservation Guidelines

Disclaimer: Cost estimates and project timelines are approximate and vary based on specific site conditions, material selections, and project scope. Consult licensed contractors for accurate quotes. Historic district requirements vary by property location and proposed work scope—verify specific requirements with the Lawrence Historic Resources Commission before beginning projects in designated districts.