Last Updated: January 4, 2026

Is your cracked driveway making your property look dated? Or perhaps you’re expanding your commercial facility and need to remove an old concrete pad? Concrete demolition and removal in Lawrence, KS involves more than just breaking up concrete and hauling it away—it requires careful planning, proper permits, specialized equipment, and knowledge of local regulations that many property owners overlook until it’s too late.

Whether you’re a business owner preparing for a commercial renovation or a property manager dealing with deteriorating infrastructure, understanding the demolition process can save you thousands of dollars and weeks of delays. From navigating Douglas County permit requirements to coordinating with Evergy for utility line markings, the details matter significantly in this specialized field.

Quick Answer: What You Need to Know

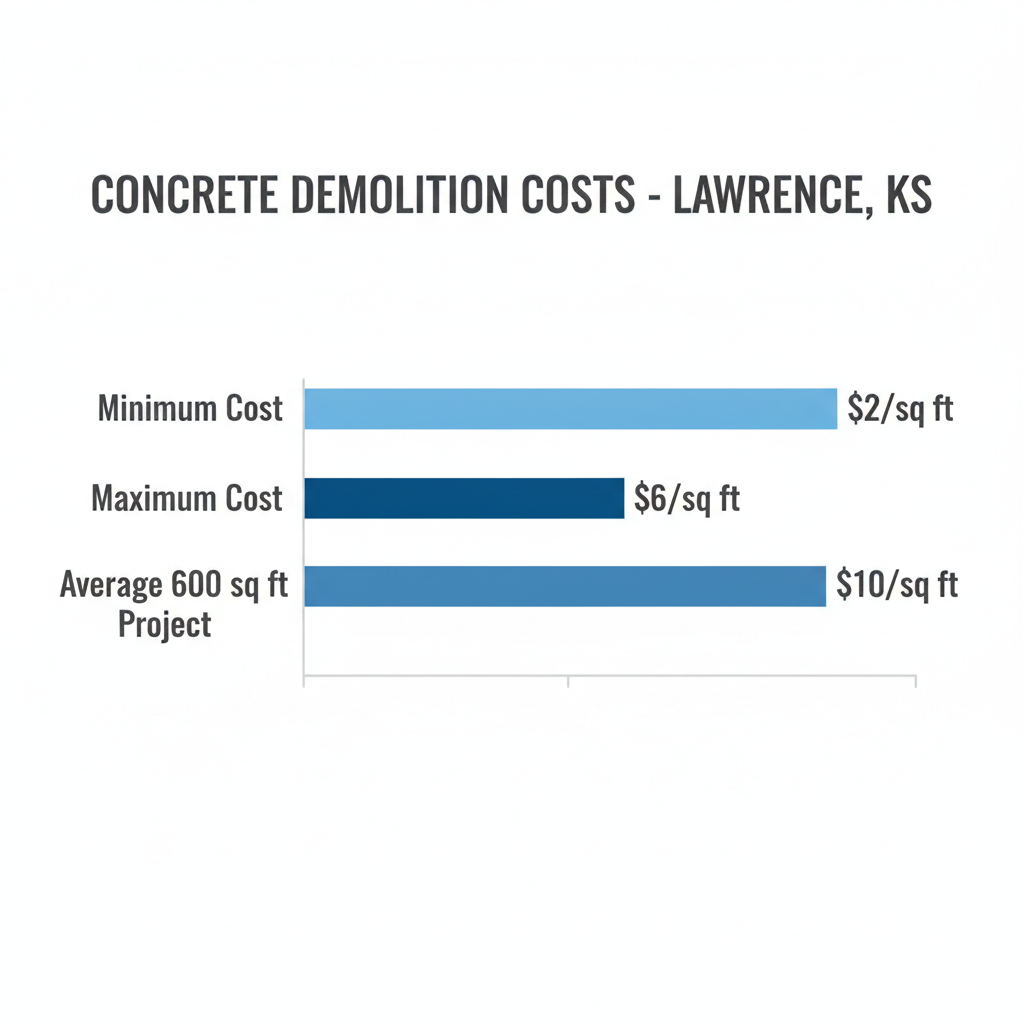

Concrete demolition and removal Lawrence KS typically costs between $2-$6 per square foot depending on thickness, accessibility, and disposal requirements. Commercial projects require city permits and utility coordination, with most demolition completed in 1-3 days for standard projects. Proper planning and licensed contractors ensure compliance with local regulations.

Key Takeaways:

- Permits required from City of Lawrence for demolition work

- Utility coordination with Evergy and Kansas Gas Service is mandatory

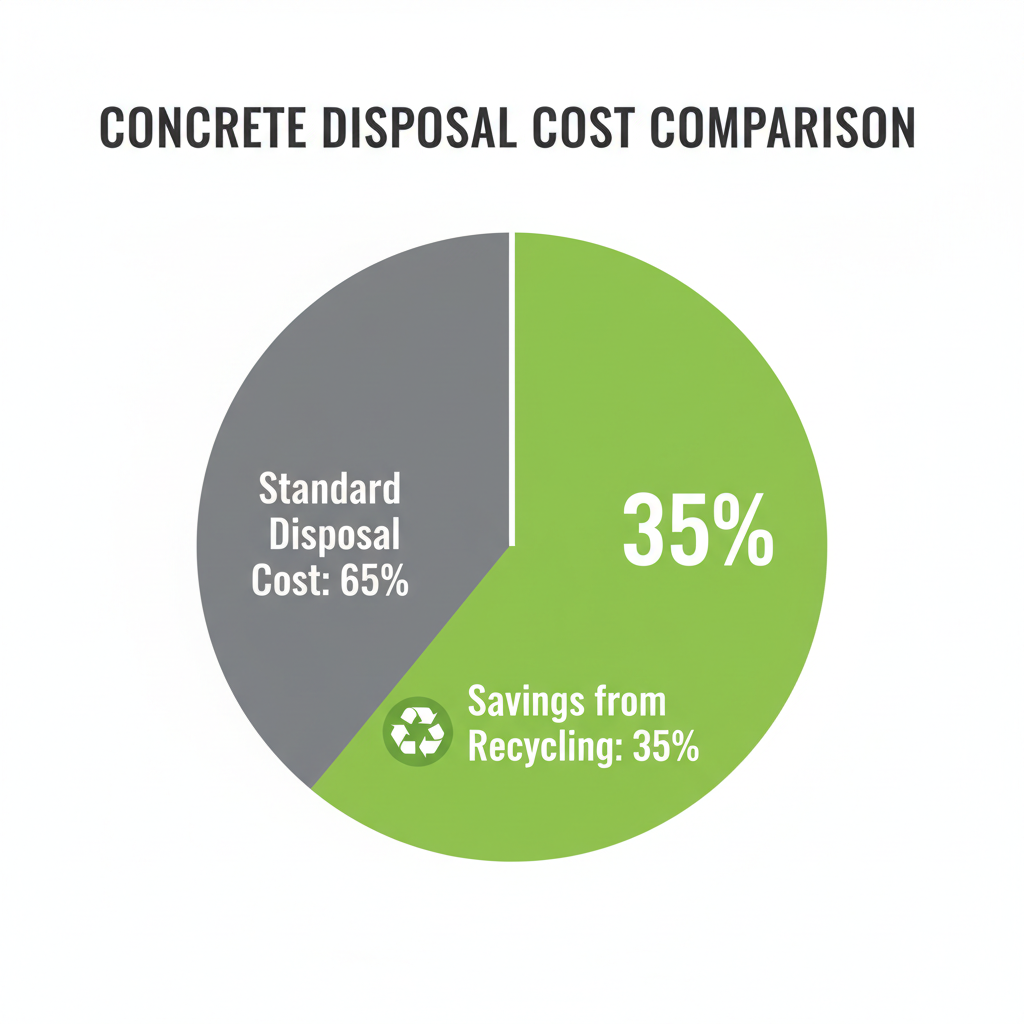

- Concrete recycling reduces disposal costs by 30-40%

- Lawrence’s freeze-thaw cycles create unique demolition challenges

- Historic preservation review may apply within 250 feet of landmarks

Understanding Concrete Demolition Costs in Lawrence, KS

When our team evaluates concrete demolition projects in Lawrence, KS, we encounter significant cost variations based on project specifics. Commercial property owners throughout zip codes 66044, 66046, and 66049 should expect different pricing structures than residential clients due to scale, accessibility, and disposal requirements.

The cost to remove a 600-square-foot commercial driveway typically runs approximately $6,000, though this varies with concrete thickness and reinforcement. Factors affecting your total investment include equipment access, proximity to property lines, underground utilities, and whether the concrete contains rebar or wire mesh reinforcement.

Cost Variables for Commercial Projects

Several elements dramatically impact demolition pricing in Douglas County. Concrete thickness is the primary factor—standard 4-inch residential slabs cost significantly less to remove than 8-inch commercial pads designed for heavy equipment. Reinforced concrete with extensive rebar networks requires specialized cutting equipment and additional labor hours.

Site accessibility affects equipment choices and project timelines. Properties along Massachusetts Street or near the intersection of 6th and Wakarusa require different approaches than open commercial lots. Tight urban spaces may necessitate smaller equipment or hand demolition, increasing labor costs by 40-60% compared to open-access sites.

| Project Type | Average Cost Range | Timeline |

|---|---|---|

| Small commercial pad (200-400 sq ft) | $800-$2,400 | 1 day |

| Standard driveway (600 sq ft) | $4,000-$6,000 | 1-2 days |

| Large parking lot section (1,000+ sq ft) | $6,000-$15,000+ | 2-5 days |

| Reinforced foundation removal | $3,000-$8,000 | 2-3 days |

Disposal and Recycling Options

Concrete recycling significantly reduces project costs while supporting environmental sustainability. Lawrence-area recycling facilities process demolished concrete into aggregate base material for road construction and new concrete production. When we recycle demolition material, clients typically save 30-40% on disposal fees compared to landfill dumping.

Due to Kansas’s emphasis on sustainable construction practices, many commercial property owners now specify recycled aggregate in their project bids. This creates a beneficial cycle where demolished concrete from older Lawrence structures becomes the foundation for new development throughout Douglas County. For more information on replacement costs after demolition, explore our guide on cost to replace concrete driveway Lawrence KS.

Common Mistakes in Concrete Demolition Projects

In our experience working throughout Lawrence, KS, we’ve witnessed costly mistakes that delay projects and inflate budgets. Commercial property managers and business owners can avoid these pitfalls by understanding local requirements and industry best practices before demolition begins.

Skipping Utility Location Services

The most dangerous and expensive mistake is failing to coordinate with utility providers before demolition. Kansas Gas Service and Evergy maintain extensive underground infrastructure throughout Lawrence. Striking a gas line or electrical conduit during demolition creates immediate safety hazards and can result in five-figure repair bills plus regulatory penalties.

Kansas law requires calling 811 at least two business days before excavation or demolition. This free service coordinates utility marking across all providers. Properties near the University of Kansas campus or downtown Lawrence often have complex utility networks that require additional coordination time beyond the standard 48-hour notice.

Ignoring Historic Preservation Requirements

The City of Lawrence maintains strict historic preservation ordinances that many property owners discover too late. Any demolition within 250 feet of designated landmarks requires Historic Resources Commission review. Properties in Old West Lawrence or along Vermont Street may face additional scrutiny and permit requirements that extend project timelines by weeks or months.

Before scheduling demolition, verify your property’s location relative to historic districts with the City of Lawrence planning department. This simple step prevents expensive project delays and potential legal complications from unauthorized demolition in protected areas.

Underestimating Weather Impact

Due to Kansas freeze-thaw cycles, Lawrence concrete often contains micro-fractures that aren’t visible on the surface. When our team begins demolition, we frequently encounter concrete that’s far more deteriorated internally than external inspection suggests. This hidden damage can increase demolition time by 20-30% as weakened concrete breaks unpredictably.

Winter demolition projects face additional challenges. Frozen ground complicates excavation beneath concrete slabs, while ice formation in existing cracks can cause unexpected fragmentation patterns. Scheduling demolition during Lawrence’s spring or fall seasons typically yields more predictable results and smoother project execution.

Best Approaches for Commercial Concrete Removal

Successful concrete demolition and removal in Lawrence, KS requires strategic planning that accounts for local conditions, regulatory requirements, and project-specific challenges. Commercial properties demand different approaches than residential work, particularly when business operations must continue during demolition.

Selecting the Right Demolition Method

Hydraulic breakers mounted on excavators provide the most efficient demolition for large commercial slabs. These machines deliver controlled impact force that fractures concrete into manageable pieces for removal. For properties with limited access near downtown Lawrence or established neighborhoods, smaller skid-steer mounted breakers offer flexibility without sacrificing effectiveness.

Sawcutting becomes essential when removing partial sections or working adjacent to structures you’re preserving. We use diamond-blade saws to create clean edges that prevent vibration damage to nearby buildings—critical for properties along busy corridors like Iowa Street or 23rd Street where neighboring businesses remain operational during your demolition.

For noise-sensitive locations or projects requiring minimal vibration, chemical expansion agents offer an alternative approach. These materials expand within drilled holes, creating controlled fractures over 24-48 hours. While slower than mechanical methods, this technique works exceptionally well for properties near the KU Medical Center or residential areas where noise ordinances restrict conventional demolition hours.

Coordinating Site Logistics

Commercial demolition requires careful coordination to minimize business disruption. We establish equipment staging areas that maintain customer access and loading dock functionality throughout the project. For retail properties or office buildings, weekend or after-hours demolition often justifies the premium labor costs by preserving normal business operations.

Debris removal logistics significantly impact project efficiency. Commercial demolition generates substantial material volume—a 1,000-square-foot concrete pad produces approximately 40-50 tons of debris. Proper planning ensures trucks can access loading areas without blocking traffic on busy Lawrence streets or creating safety hazards for pedestrians near downtown intersections.

Working with Licensed Contractors

Selecting qualified contractors protects your investment and ensures regulatory compliance. Verify that demolition contractors carry appropriate insurance coverage including general liability and workers’ compensation. Lawrence Concrete Pros, along with other licensed contractors in Douglas County, maintains proper licensing and insurance to protect property owners from liability during demolition work.

Request detailed proposals that specify disposal methods, project timelines, and permit responsibilities. Professional contractors handle permit applications, utility coordination, and final site cleanup as part of their service package. This comprehensive approach prevents the coordination headaches that plague DIY demolition attempts or projects managed by underqualified contractors. Learn more about professional approaches in our article on professional concrete services Lawrence KS.

Step-by-Step: Planning Your Demolition Project

Executing a successful concrete demolition project in Lawrence, KS follows a structured process that ensures safety, regulatory compliance, and cost control. Commercial property owners benefit from understanding each phase before work begins.

Phase 1: Assessment and Planning

Begin with a thorough site evaluation that documents concrete thickness, reinforcement type, and accessibility constraints. Professional contractors use ground-penetrating radar or core samples to identify subsurface conditions that affect demolition approaches. This assessment reveals potential complications like unexpected utilities or contaminated soil beneath the concrete.

Develop a project timeline that accounts for permit processing, utility coordination, and weather windows. In Lawrence, allow 7-10 business days for standard demolition permits, with additional time if historic preservation review applies. Winter projects should include contingency time for weather delays—Kansas ice storms can halt outdoor work for days at a time.

Phase 2: Permits and Utility Coordination

Submit demolition permit applications to the City of Lawrence Building Safety Division with detailed site plans showing the concrete to be removed. Applications require property owner authorization, contractor licensing verification, and disposal method documentation. Properties near University of Kansas facilities or within historic districts undergo additional review that extends approval timelines.

Contact Kansas 811 at least 48 hours before demolition to initiate utility marking. Evergy, Kansas Gas Service, and telecommunications providers will mark their infrastructure with colored flags and paint. Never proceed with demolition until all utilities have been marked and you’ve verified marking completeness with each provider.

Phase 3: Execution and Site Restoration

Professional demolition crews establish safety perimeters and deploy equipment appropriate for your site conditions. Hydraulic breakers fracture the concrete systematically, working from edges toward the center to prevent uncontrolled cracking into adjacent areas. Sawcutting creates clean separation lines where demolition meets existing structures you’re preserving.

As concrete breaks into manageable pieces, excavators load debris into trucks for transport to recycling facilities or disposal sites. Final site cleanup includes removing concrete fragments from surrounding areas, compacting exposed soil to prevent settling, and ensuring proper drainage grading. Quality contractors leave sites ready for immediate replacement work or alternative use. For comprehensive replacement information, review our guide on concrete driveway replacement in Lawrence KS.

Lawrence Regulations and Permit Requirements

The City of Lawrence enforces specific regulations governing concrete demolition and removal that protect public safety and preserve the community’s historic character. Understanding these requirements prevents project delays and potential penalties for non-compliance.

Standard demolition permits cost $50-$200 depending on project scope, with fees determined by the total square footage of concrete removal. Commercial projects typically require engineered site plans showing demolition boundaries, adjacent structures, and utility locations. Submit applications to the Building Safety Division at City Hall with at least 10 business days lead time before your planned start date.

Properties within historic overlay districts face additional scrutiny under Lawrence Municipal Code. The Historic Resources Commission reviews demolition proposals to ensure work doesn’t compromise historically significant structures or streetscapes. This process adds 2-4 weeks to project timelines but protects Lawrence’s architectural heritage near landmarks like the Eldridge Hotel or properties along Massachusetts Street’s historic corridor.

Douglas County environmental regulations govern concrete disposal and recycling. Contractors must document proper disposal methods and may need to provide recycling receipts as proof of environmental compliance. These requirements align with Kansas’s broader initiatives to reduce construction waste in landfills throughout the region.

FAQ: Concrete Demolition in Lawrence, KS

How long does typical concrete demolition take?

Most commercial concrete demolition projects in Lawrence, KS complete within 1-3 days depending on size and complexity. A standard 600-square-foot driveway removal typically finishes in one day, while large parking lot sections or heavily reinforced foundations may require 3-5 days. Weather conditions and accessibility challenges can extend these timelines.

Do I need a permit for concrete demolition in Lawrence?

Yes, the City of Lawrence requires demolition permits for most concrete removal projects. Small repairs under 100 square feet may be exempt, but commercial demolition always requires proper permits. Properties within 250 feet of historic landmarks need additional Historic Resources Commission approval, which extends the permitting timeline significantly.

What happens to demolished concrete?

Responsible contractors recycle demolished concrete into aggregate base material for road construction and new concrete production. Lawrence-area recycling facilities process crushed concrete that meets Kansas Department of Transportation specifications. Recycling reduces disposal costs by 30-40% compared to landfill dumping while supporting environmental sustainability goals.

Can demolition damage my property’s foundation?

Professional contractors use controlled demolition techniques that minimize vibration transmission to adjacent structures. Sawcutting creates clean separation lines between demolition areas and existing foundations. Proper equipment selection and experienced operators prevent the foundation damage that occurs when unqualified contractors use excessive force or inappropriate machinery. For foundation-related concerns, consult our guide on expert concrete repair in Lawrence KS.

How does Kansas weather affect demolition costs?

Lawrence’s freeze-thaw cycles create internal concrete deterioration that’s invisible from the surface. This hidden damage can increase demolition time by 20-30% as weakened concrete fractures unpredictably. Winter projects face additional costs from frozen ground conditions and weather delays. Spring and fall typically offer the most predictable conditions for cost-effective demolition work.

Conclusion: Planning Your Lawrence Demolition Project

Successful concrete demolition and removal in Lawrence, KS requires understanding local regulations, selecting appropriate demolition methods, and working with qualified contractors who navigate Douglas County’s specific requirements. Commercial property owners who invest time in proper planning avoid costly delays and budget overruns that plague rushed projects.

From coordinating with Evergy and Kansas Gas Service to securing Historic Resources Commission approval when needed, each step in the demolition process protects your investment and ensures regulatory compliance. The 30-40% cost savings from concrete recycling combined with efficient project execution make professional demolition services a valuable investment for Lawrence businesses.

Whether you’re preparing for facility expansion, addressing deteriorating infrastructure, or clearing space for new construction throughout zip codes 66044, 66046, and 66049, proper demolition creates the foundation for your next project phase. Partnering with experienced contractors who understand Lawrence’s unique climate challenges and regulatory environment ensures your demolition project proceeds smoothly from permit application to final site cleanup. For pricing specifics on your next project, explore our comprehensive breakdown of concrete slab cost per square foot in Lawrence KS.

Sources and References

- City of Lawrence, Kansas – Building Safety Division: https://lawrenceks.gov/

- Kansas Department of Transportation – Construction Specifications

- Douglas County, Kansas – Environmental Regulations

- Kansas 811 – Utility Notification Service